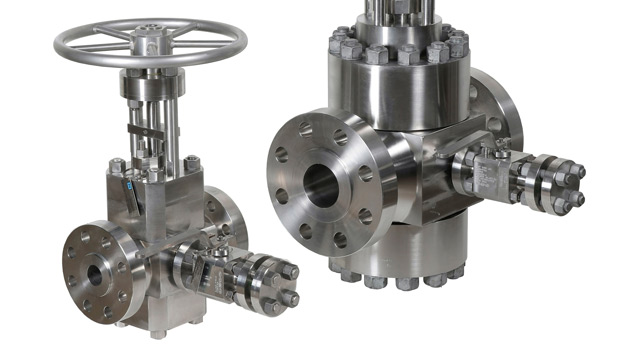

THROUGH CONDUIT GATE VALVES

A Through Conduit Gate Valve is a specialized type of gate valve designed to offer full-bore, unobstructed flow when in the open position, ensuring minimal pressure drop and turbulence in pipeline systems. It is widely used in industries where smooth flow, low-pressure loss and operational flexibility are critical, especially in oil and gas, petrochemical, and other high-pressure applications. These valves are ideal for pigging operations due to their design, which allows pipeline pigs to pass through without any obstruction.

Through Conduit Gate Valves can be divided into two different types:

Slab Gate Valves

• Features a single slab that moves up and down between the seats.

• Provides reliable sealing in high-flow applications and offers a cost-effective solution for basic on/off control.

• Suitable for high-pressure systems, but does not provide as tight a seal as an expanding gate in low-pressure applications.

Expanding Gate Valves

• This type of valve has two segments that expand against the seats, forming a tighter seal.

• it is typically used in critical applications where zero leakage is required, both in high and low-pressure environments.

• Expanding Gate Valves are often favored in isolation and emergency shutoff applications, where reliable sealing is essential for safety.

SUITABLE APPLICATIONS

| • Chemical processing | • Nitrogen service |

| • Oil & Gas services | • Shipbuilding industry |

| • Water treatment service | • Drilling mud service |

| • Power generation | • Cold start air |

| • Completion fluids | • Cement service |

| • Food & Beverage industry | • Marine industry |

UNIQUE FEATURES

| • Precise flow control | • Reliable performance |

| • Excellent shut-off capability | • Robust design |

| • Minimal pressure drop | • Versatility |