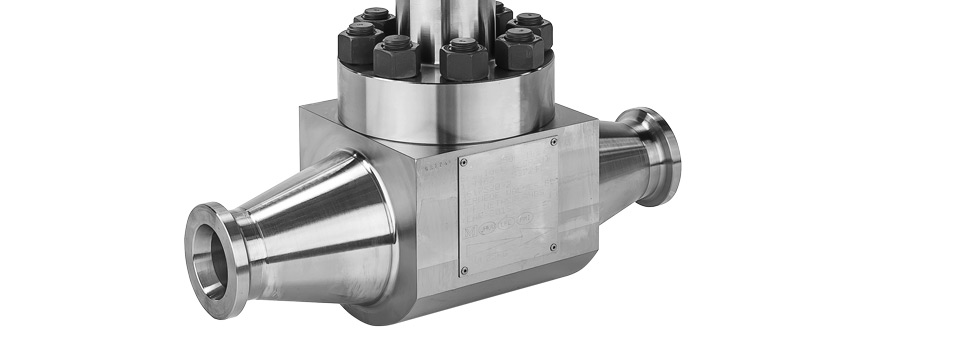

GLOBE VALVES

Globe valves stand as stalwarts in the domain of fluid control, prized for their ability to regulate the flow of liquids, gases, and steam with unparalleled precision. Globe valves offer versatility, reliability, and precise control over fluid flow.

Globe valves belong to the family of linear motion valves and derive their name from the globular shape of their body. Their design comprises a movable disc (the plug or disc) that regulates flow by moving up and down against the stationary seat. This unique mechanism allows for fine-tuning of flow rates and provides excellent throttling capability, making globe valves ideal for applications requiring precise control.

Globe valves play a pivotal role in fluid control systems, offering precision, reliability, and versatility across diverse industries and applications. Their ability to provide accurate flow regulation, excellent shut-off capability, and low maintenance requirements makes them indispensable components in steam systems, HVAC systems, process industries, and water treatment facilities. As technology advances and industrial demands evolve, globe valves continue to uphold their reputation as indispensable tools for achieving optimal performance and efficiency in fluid handling operations.

SUITABLE APPLICATIONS

| • Steam service | • Marine industry |

| • HVAC systems | • Shipbuilding industry |

| • Cryogenic service | • Power Generation |

| • Process industry | • Food & Beverage industry |

| • Water treatment service |

UNIQUE FEATURES

| • Precise flow control | • Versatility |

| • Low maintenance | • Excellent shut-off capability |

| • Throttling capability |