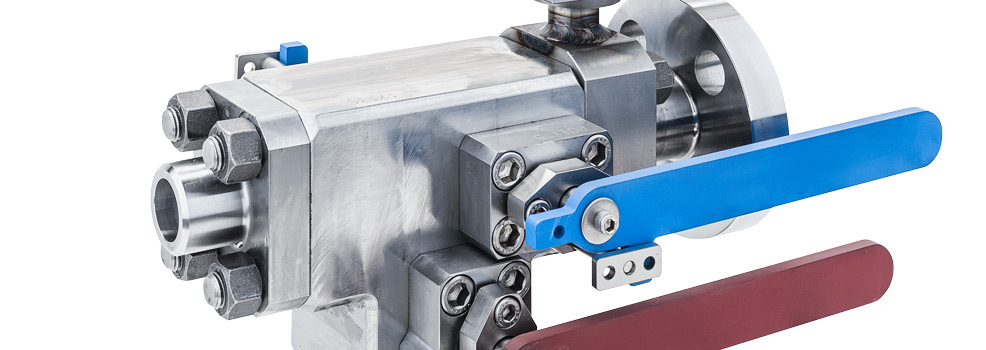

INSTRUMENTATION VALVES

Instrumentation valves are critical components in the management and control of fluid systems in various industrial processes. These valves are designed to ensure precise control, isolation, and direction of fluid flow within instrumentation systems, which are used to measure, monitor, and control pressure, temperature, flow, and other parameters.

These valves require a different (engineering) approach than other valves in the industry. However, for us, these valve types are common practice. From needle valves, straight type to customized manifold valves with optimal CV values.

SUITABLE APPLICATIONS

| • Precise flow control | • Versatility |

| • Oil and Gas Industry | • HVAC systems |

| • Chemical Processing | • Hydraulic & Pneumatic systems |

| • Power Generation | • Marine industry |

| • Water Treatment | • Food & Beverage industry |

| • Pharmaceutical industry |

UNIQUE FEATURES

| • Compact and modular design | • Busy maintenances |

| • Multiple flow parts | • Tight shut off |

| • High pressure resistance | • Corrosion & Chemical resistance |

| • High temperature resistance |

Technical Specifications

Size inch (DN)

1/2" (15) - 2” (50)

ANSI class (lbs)

150 - 4500

API rating (psi)

3000 - 15000

DIN rating (PN)

10 - 400

ASME B16.34

DIN

PED

Manufacturer standard

Pressure

Vacuum to 1034 bar(g)

Pressure

Vacuum to 15000 psi

Temperature

-196°C to +850°C

Temperature

-320°F to +1562°F

Modular

Manufacturer standard

ISO 5208

EN 12266 Part 1/2

Clients’ specification

Flanged (FF / RF / RTJ)

Butt Weld

Socket Weld

Threaded (Male / Female)

Hubbed or Mechanical Ends

SAE Flanged

Compact Flanged

Clients’ specification