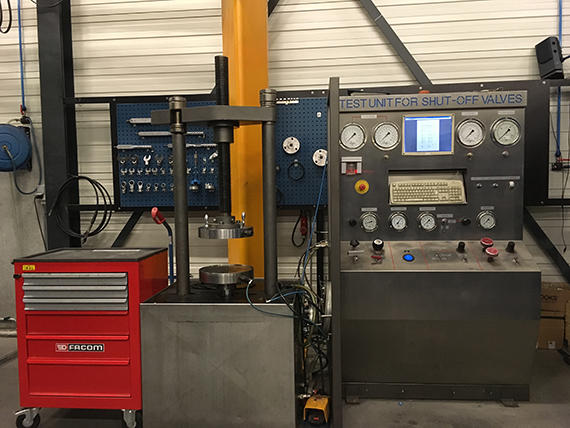

Merwede Valves B.V. test facility

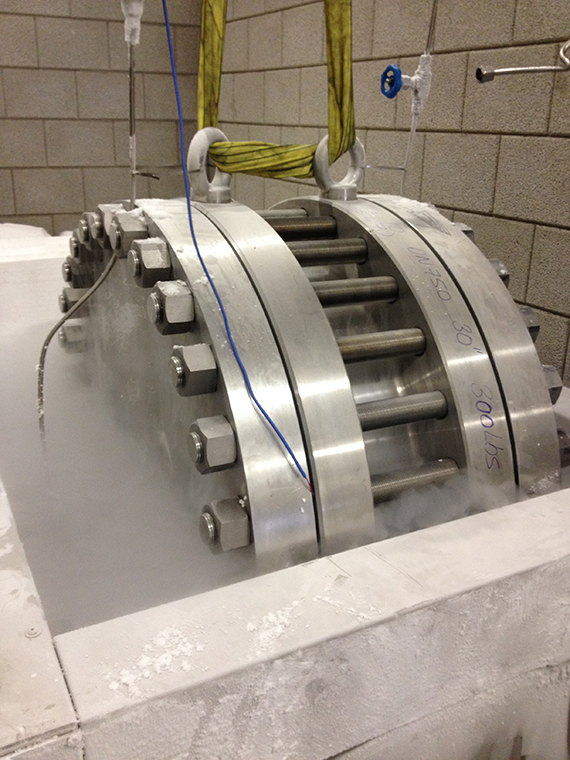

Merwede Valves B.V. have in-house test facilities to perform all possible valve production and final acceptance testing. We test against international standards and to do so we have a test facility that is fully equipped with various test benches, pressure gauges, digital gauges, flow meters and leak rate determination. There have been installed three cryogenic test tanks with a maximum volume of 2500 Liter N2, which enable us to test at low temperature. Our test facility complies to European and national health and safety regulations.

On a daily base Merwede Valves B.V. performs valve tests according the following standards: API, ASME, BS, EN, ISO, Fugitive emission, Shell Mesc codes, Shell TAT. We also facilitate to have our valves fire safe tested and we test according customer’s and project’s specifications, too.

Pressure range varies from vacuum to 1500 Bar. Hydrostatic test is being done with demi water, HP gas test with Nitrogen gas or HP gas with Helium gas.

Size range is 10 mm – 1200 mm or ¼”- 48” inch with BW ends, socket weld ends, threaded and flanged ends, mechanical joints etc.

A safety bunker is installed to do high pressure gas and cryogenic testing. The bunker is equipped with an extraction unit for nitrogen gas, monitoring of oxygen levels and video monitoring from a safe position for the operator.

Fugitive emission test are performed by means of helium leak testing with tracer gas or by sniffer method against international standard. All tests are performed by trained and certified personnel according ISO 9712 LT level II.